From Visualization to Future Prediction

Make your manufacturing site smarter

By combining IoT × AI × Cloud, we enable real-time visualization of factory power consumption and operational status — and forecast future performance. Accelerate onsite improvements through effective data utilization.

Smart Factory Solutions by Orange Box

From IoT device data collection to cloud storage, AI analysis, and onsite response —

we provide a simple, reliable solution even for complex system deployments.

Visualization, Analysis, and

Instant Response

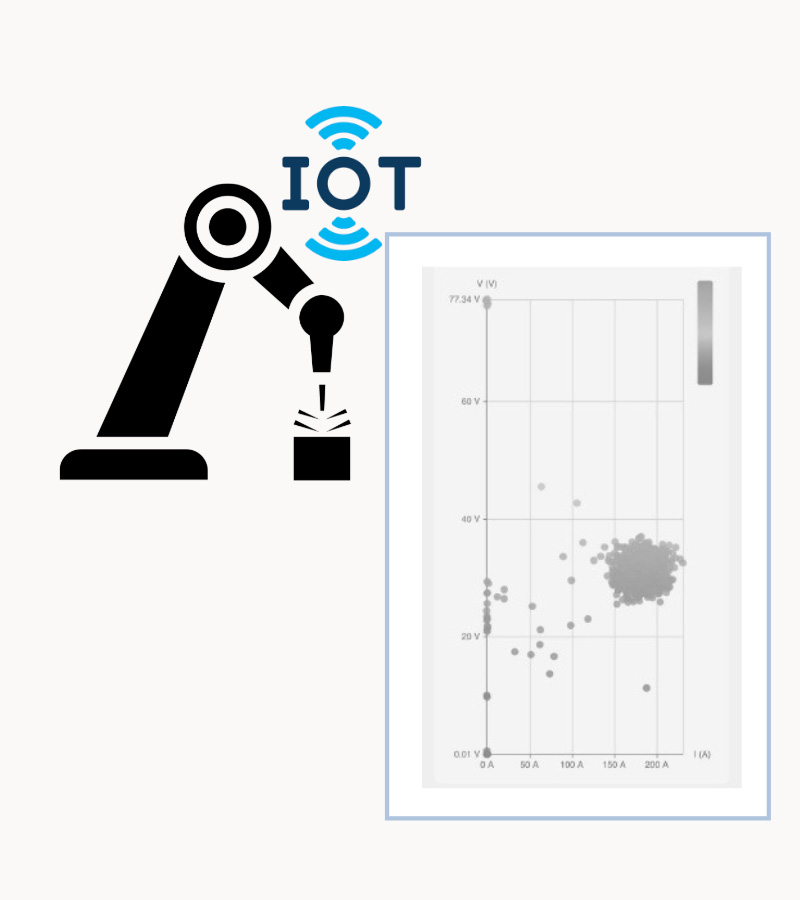

IoT Data Collection & Cloud Storage

Our IoT devices automatically collect power and operating data from various equipment. The data is securely stored in the cloud, enabling centralized, real-time monitoring across multiple sites.

AI Analysis & Prediction on GPU Servers

Using high-performance GPU servers, AI processes the accumulated data at high speed — detecting anomalies, optimizing energy usage, and predicting equipment failures. We have a proven track record of implementing GPU servers in manufacturing environments.

Real-Time Monitoring via PDA

Collected and analyzed information can be accessed in real time via PDA or smart devices. Onsite staff can quickly check equipment status and alerts to enable prompt decision-making and action.

Use Case: Visualizing and

Improving Welding Processes

In welding production, operations often rely on skilled workers’ intuition and experience, which causes inconsistencies and inefficient energy use. Our solution addresses this by:

This data-driven workflow helps stabilize quality, boost productivity, and accelerate improvement cycles.

Service Implementation Process

- Initial Consultation

- We gather detailed information about your factory scale, equipment configuration, IoT devices required, and objectives. We also discuss installation options (handled by you or arranged by us).

- Proposal & Quotation

- Based on provided plant layouts and power panel photos, we propose optimal hardware/software configurations — and optionally conduct a site survey. A clear quote is prepared including IoT devices, server setup, software, and installation.

- Contract Signing

- Upon agreement, we formalize the contract and finalize the project schedule and delivery dates.

- IoT Hardware Deployment

- We install IoT devices at your factory for power measurement and operational data collection. If self-installing, we provide an installation manual.

- Server & AI Environment Setup (Optional)

- For customers requiring it, we build the cloud environment and GPU servers to analyze and visualize the collected data using AI models. We use proven high-performance GPU hardware to support energy-saving and anomaly detection.

- PDA/Web System Integration (Optional)

- We set up interfaces so PDA devices, smartphones, and web dashboards can access real-time equipment status and analysis.

- Go Live & Support

- We start full-scale operations and provide ongoing support including usage guidance, additional analysis, and troubleshooting to continuously improve onsite processes.